PROFESSIONAL

spacebead TLA superbead energystore+ Projects News

transform your build with injected insulation for walls and floors

The energystore superbead system is an injected expanded polystyrene (EPS) bead bonded with an adhesive designed for use in multiple cavity wall scenarios including masonry, party wall and timber frame.

The system has been Patented (Patent no.EP4079990) for use underneath beam and block floors.

APPLICATIONS

BEAM + BLOCK

A Patented (Patent no.EP4079990) insulation solution for beam + block floors enabling reduced overall floor construction depths, reduced material consumption and enhanced thermal performance compared to traditional methods.

MaSONRY

A full-fill insulation solution suitable for both residential and commercial construction.

PARTY WALL

The only EPS bead insulation with Robust Details for masonry construction satisfying Part E of building regulations enabling a single product to be used within the cavity and the party wall.

TIMBER FRAME

The only EPS bead insulation to have timber frame accreditation for new build construction. It offers an innovative insulation solution for timber frame which can be used in both on and off-site manufacturing.

BENEFITS

EXCELLENT THERMAL PERFORMANCE*

Declared thermal conductivity of 0.033 W/mK or 0.032 W/mK

*Compared to traditional methods

NO STORAGE OR ON-SITE WASTE

Exact amount of energystore superbead® needed is pumped on-site, leaving no insulation offcuts or waste for you to deal with.

IMPROVED PROGRAMME SPEED*

The only product that can be installed in cavity, party wall and beam + block floors in one visit.

*When using all energystore superbead® systems and compared to traditional methods

MOISTURE RESISTANT SYSTEM

Using closed cell EPS technology, energystore superbead does not absorb moisture.*

*BS EN 1609 WS (doesn’t exceed 1.0kg/m2)

WE DELIVER and INSTALL superbead

Our in house contracting division can supply and install our products giving enhanced levels of quality assurance.

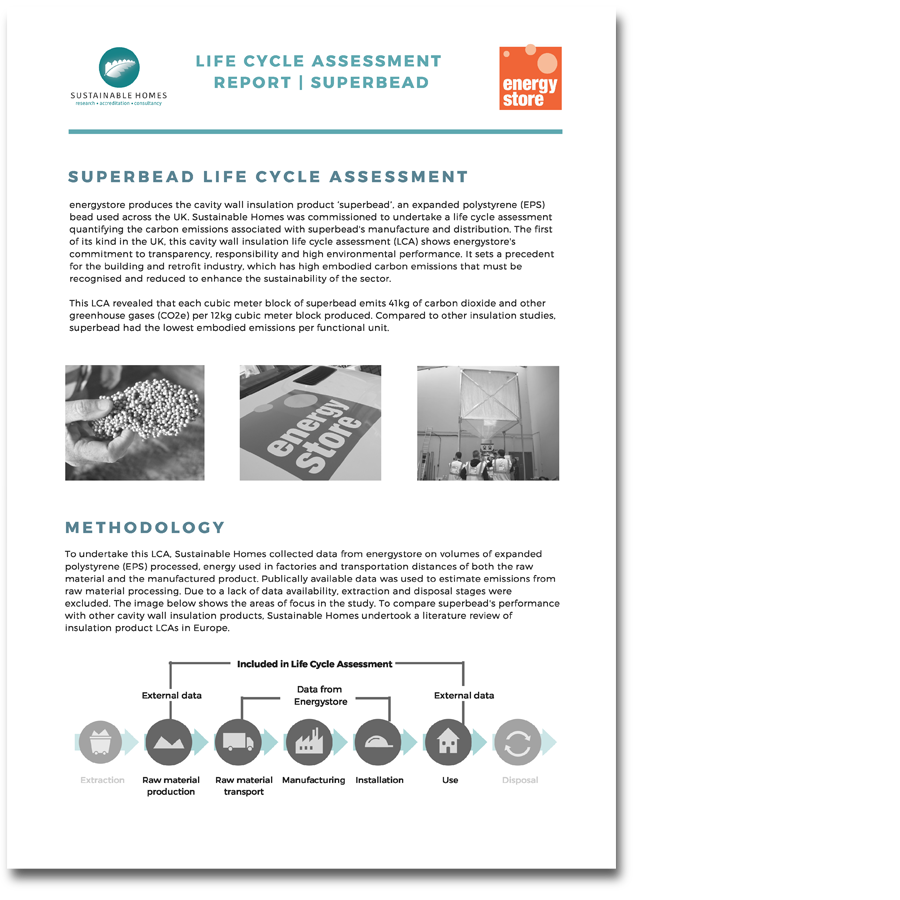

The environmental impact of energystore superbead’s manufacture, transport and installation has been independently assessed.*

*Sustainable Homes Life Cycle Assessment Report: Superbead. All information below is taken directly from the report. For the full report click here

A. Raw Material Production

Superbead emissions are from raw material processing. This is equal to 31kg of carbon emissions for each 12kg cube of EPS produced.

B. Raw Material Transport

Emissions are from raw material transport. The transportation of each 12kg cube of EPS results in 0.9kg carbon emissions on average.

C. Manufacturing Process

Emissions are from manufacturing in energystore’s factories, or 7.1kg carbon emissions per cube.

D. Superbead Installation

Emissions are from distribution of the superbead product for installation. This results in 2.1kg carbon per cube.

E. 5 Months of Payback Time

After installation in an average 3-bed home it takes approximately 5 months for superbead to save as much carbon as is released during production and transport.

approved installers ONLY

Interested in becoming an energystore approved installer?

VIEW DOCUMENTS

WANT TO TALK TECHNICAL?

Design support, SAP, U-Value, Psi-Value, CPD

LATEST NEWS

Warm words from customers

“Antrim Construction have been working with energystore for over 10 years. energystore superbead has been our choice of cavity wall insulation due to its quick onsite install and excellent thermal performance.The reliable install service energystore offer helps keep our build programme on track. We are increasingly working with energystore’s technical department to optimise the thermal performance of our new construction projects.”

Antrim Construction

“We’ve worked with energystore for a number of years and find their level of expertise and design support to be valuable and hugely beneficial to our projects. The use of energystore superbead for cwi on our timber frame domestic sites has freed up our joiners improving the speed of build programme. Since starting to use energystore TLA in 2019, we have used it on several domestic and commercial projects simplifying or build programme and reducing the hassle of using board on site. We’re delighted with the results and look forward to continuing our relationship with energystore for many years to come.”

MSM Contracts

“Baxter Kelly have been working with Energy Store Ltd for about two years now, and they are a true pleasure to do business with. Always professional yet easy going, we have been impressed with their commitment to high levels of customer service, and especially their willingness to go above and beyond to ensure customer satisfaction – and, from a business perspective, their commitment to speedy deliveries! Their years of experience make for a high-quality product, and we look forward to many more years of partnership.”

Baxter Kelly